A reminder as to what the stove used to look like

The new cast iron panels required drilling,....

tapping,....

... and painting

Reusable parts were wire brushed and repainted

The manky old insulation was discarded

The front panel is loosely attached to the base plate

The four oven panels are loosely assembled using fire cement on the joints

Superwool 607 Insulation Material is placed under the oven

The oven is slid into the flange on the front panel

The inner back plate is fitted and held in place with a sash cramp. All fasteners are now tightened and surplus fire cement removed

The inner firebox side is fitted,....

... followed by the outer firebox side

The step is filled with insulation.

More insulation is laid on the inside of the RH end panel,....

which is then fitted in place.

Attention is now turned to the LH end

Insulation is fitted ..

.. followed by the end panel.

The new fire bricks require modifying to mate correctly with the old ones. This is hard on the cutting discs.

The fire bricks dovetail nicely into place.

Another view of the assembled fire bricks. You're right. I don't know my left from my right!

The stiffening plate is bolted to the bottom the top plate..

.. and the fiddle rails to the top.

The sash cramp is replaced with a ratchet strap and more insulation inserted. Fire cement will be applied to the top of the fire bricks

The top panel is screwed down and insulation fitted over the inner back panel.

The sheet metal outer back panel is fitted in place.

The smoke box securing lug had broken off the top panel ..

.

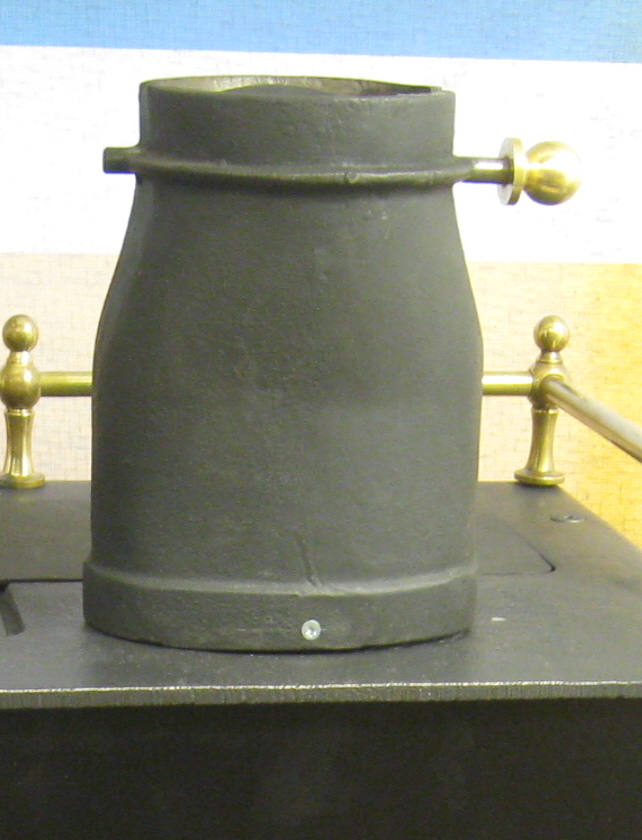

.. so the smoke box was attached with two screws at the front

.. and one at the rear

Doors, hot plates, grate and ashpan in position.

The finished stove ready to install.

A few details:

The fire bricks and iron castings came from Brenmarl Engineering.

http://www.narrowboatbrassware.co.uk/

If only replacing some of the bricks they may need modifying with an angle grinder and stone cutting disc, as the interlocking method is different for later bricks.

The insulation is Super Wool 607. We bought ours from RS Components:-

https://uk.rs-online.com/web/p/thermal-insulating-sheets/8405529/

This material is also available from suppliers of refractory ovens for baking pottery or pizzas.

The stove paint we used was Calfire Stove Bright, Flat black:

https://www.thestovecompany.co.uk/high-temperature-stove-paint/brush-on-high-temperature-stove-paint